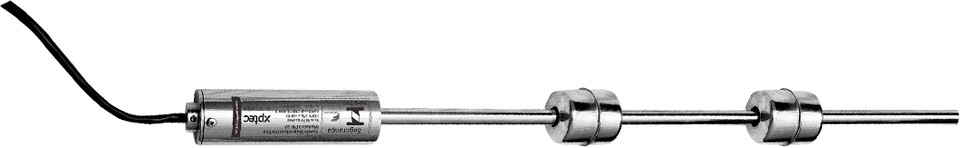

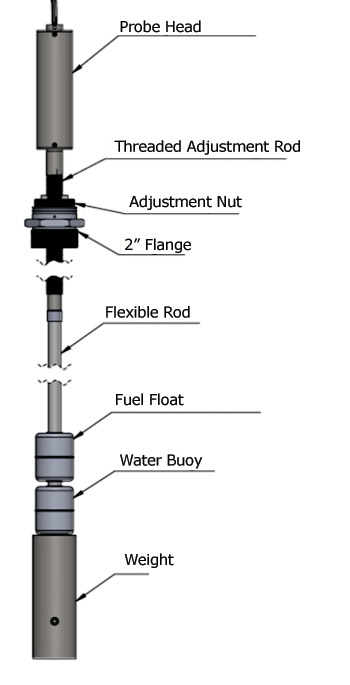

The XPB-22 Flex Probe is a highly reliable and accurate liquid level measuring device, suitable for measuring stocks in vertical storage tanks up to 20m high.

It operates under the principle of magnetostriction, the most advanced technology on the market. As it operates without mechanical contact, it does not wear out, is maintenance-free and has a high durability. Additionally, it does not require calibration and allows continuous, real-time monitoring.

Due to its flexibility, it can be rolled up compactly, greatly reducing transportation and installation costs.

It allows the measurement of two levels of products with different densities, such as fuel tanks, monitoring both the level of the product and the water level at the bottom of the tank. It has up to 7 temperature sensors incorporated along the length of the probe, a relevant feature for the precise compensation of the liquid volume at a reference temperature.

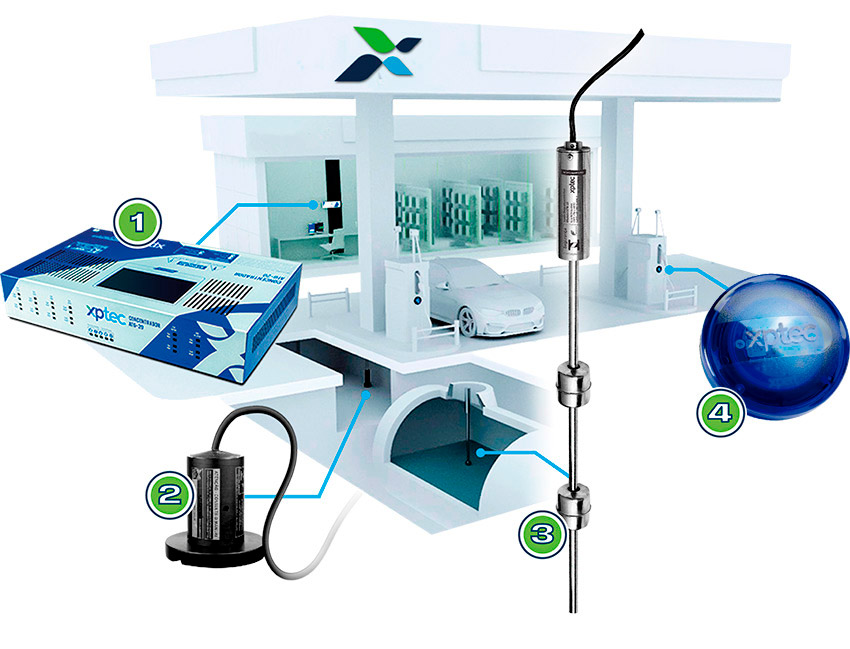

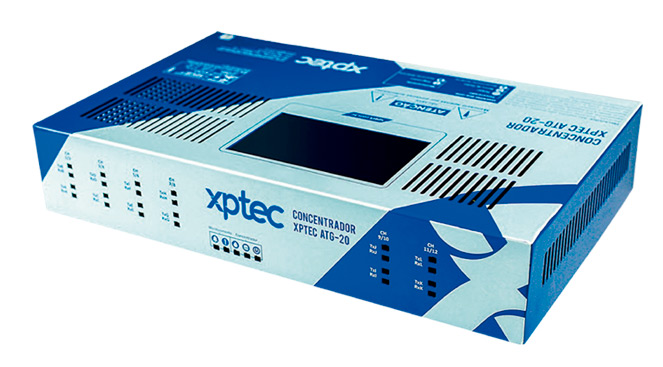

Connected to a measuring hub (Console), it allows you to manage inventory in real time, efficiently and automatically, both locally and remotely. Additionally, alarms can be incorporated, such as maximum and minimum levels.

Availability of intrinsic safety barrier for operation in conjunction with third-party concentrators, required for installations in potentially explosive areas.